Anthracene: Properties, Production and Uses

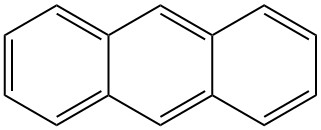

Anthracene is a solid polycyclic aromatic hydrocarbon with the formula C14H10 that is composed of three fused benzene rings. It is a component of coal tar and was discovered in 1832 by J. Dumas and H. A. Laurent. Anthracene is colorless but exhibits a blue fluorescence under ultraviolet radiation.

Table of Contents

1. Physical Properties of Anthracene

Anthracene is a colorless solid that has a molecular weight of 178.24 g/mol, a melting point of 218 °C, and a boiling point of 340 °C at 101.3 kPa. It exhibits a blue-violet fluorescence and can sublime, meaning it transitions directly from a solid to a vapor.

Anthracene can form mixed crystals with phenanthrene and carbazole in binary and ternary systems.

Anthracene has slight solubility in benzene, chloroform, and carbon disulfide, less solubility in diethyl ether and ethanol, and is nearly insoluble in water.

Anthracene has a specific heat capacity of 1164 J/kg at 24 °C, a heat of fusion of 162 kJ/kg, a heat of vaporization of 294 kJ/kg, and a heat of combustion of 40110 kJ/kg at 25 °C.

2. Chemical Reactions of Anthracene

Anthracene can undergo various chemical transformations under specific conditions:

1. UV Light Irradiation: When exposed to UV light in the absence of oxygen, anthracene is converted to dianthracene.

2. Oxidation with Oxygen: In the presence of oxygen, anthracene reacts by adding oxygen to the 9,10-positions, resulting in the formation of a peroxide compound

3. Pyrocondensation: Through pyrocondensation, anthracene can yield two products, namely 2,9-bianthryl and 9,10-dihydroanthracene.

4. Hydrogenation: Anthracene can be readily hydrogenated to produce 9,10-dihydroanthracene. Using homogeneous ruthenium catalysts, it can further undergo hydrogenation to yield 1,2,3,4-tetrahydroanthracene and subsequent hydrogenation can lead to the formation of 1,2,3,4,5,6,7,8-octahydroanthracene.

5. Oxidation: When subjected to oxidation, either in the liquid or gas phase, anthracene transforms into anthraquinone.

6. Halogenation, Nitration, and Sulfonation: Anthracene primarily undergoes halogenation and nitration at the 9- and 10-positions and sulfonation at the 1- or 2-position, depending on the specific reaction conditions.

7. Diels-Alder Addition: Anthracene is capable of undergoing Diels-Alder addition reactions with dienophiles such as maleic anhydride. These additions typically occur at the 9- and 10-positions.

8. Magnesium Reaction: Anthracene can react with magnesium metal in tetrahydrofuran (THF) to form a magnesium-anthracene adduct. This adduct can be further processed to obtain highly reactive magnesium, which can subsequently be converted into magnesium hydride and Grignard reagents.

These chemical reactions illustrate the versatility of anthracene in various synthetic processes and its potential for forming diverse organic compounds under specific conditions.

3. Production of Anthracene

3.1. Extraction of anthracene from coal tar

Anthracene is extracted from high-temperature coal tar by continuous tar distillation. The fraction that boils between 300 and 360 °C, known as anthracene oil I, is concentrated to contain approximately 7% anthracene.

This oil is then cooled and centrifuged to yield anthracene residues, which contain approximately 20-35% anthracene.

Anthracene residues can be further purified by crystallization or distillation. Distillation produces a crude product containing 45-55% anthracene, commonly known as “50s anthracene”. Enhanced-quality 50s anthracene can be obtained through a two-step continuous column distillation process.

To achieve higher purity, crude 50s anthracene can be recrystallized using selective solvents. Repeated recrystallization from a three- to four-fold excess of pyridine, for example, yields anthracene with a purity of 95% relative to its content in the 50s anthracene, with an 80% yield. Various other selective solvents can also be used for recrystallization.

3.2. Alternative extraction methods

Anthracene can also be extracted from the high-boiling oil of coal liquefaction. For carbazole-free crude anthracene, distillation and crystallization of residues from the pyrolysis of hydrocarbon fractions to olefins can be used, although these pyrolysis oils typically contain less than 1% anthracene.

Selective hydrodealkylation of the aromatic fraction containing methylphenanthrenes and methylanthracenes can enhance anthracene yields.

3.3. Synthesis of anthracene

Anthracene can also be synthesized by various methods, including hydrogenation of phenanthrene, isomerization of sym-octahydrophenanthrene to sym-octahydroanthracene, and subsequent dehydrogenation.

A mixture of sym-octahydroanthracene and sym-octahydrophenanthrene can be obtained through catalytic disproportionation of tetralin.

Additionally, anthracene can be formed from diphenylmethane in the presence of HF/BF3 at 80 °C and by the thermal reaction of o-methyldiphenylmethane at approximately 600 °C.

However, these synthetic methods are not commercially significant due to the ample availability of anthracene from coal tar.

4. Uses of Anthracene

Anthracene is a versatile organic compound with a wide range of applications. On a commercial scale, it is primarily used to produce anthraquinone, a key industrial chemical used in the production of dyes, pigments, and other chemicals.

Anthracene is also being explored for a number of alternative applications. For example, it has been proposed as a potential plasticizer for thermosetting resins and also been considered as a light stabilizer for polymers.

In the material science, anthracene derivatives are being explored as building blocks for engineering plastics. For example, the polyether of 9,10-dihydroxyanthracene is a high-performance plastic with excellent mechanical and thermal properties.

Anthracene is a crystalline organic photoconductor, which means that it can generate an electric current when exposed to light. This property makes anthracene useful in electrophotography, a technology commonly associated with photocopying and laser printing.

In its purest form, anthracene is used as a scintillant in scientific applications. Scintillants are materials that emit light when they interact with radiation.

Anthracene scintillants are particularly useful for the detection of high-energy radiation, such as gamma rays and X-rays. This use is vital in fields such as nuclear physics, where the precise measurement of radiation is of utmost importance for research and safety purposes.

5. Toxicology of Anthracene

Anthracene is a polycyclic aromatic hydrocarbon that has been investigated for its potential carcinogenicity, but pure anthracene under controlled conditions does not exhibit significant carcinogenic effects. This is supported by negative findings in numerous in vitro and in vivo genotoxicity tests.

For example, subcutaneous injections of 20 mg of anthracene in an oily solution 33 times per week resulted in local fibromas, sometimes accompanied by sarcoma-like excrescences. However, this outcome does not reflect the carcinogenic potential of pure anthracene.

In addition, an epidermal tumor initiation test on mice using pure anthracene and phorbol ester as a promoter resulted in papillomas in only a few cases (4 out of 28 animals). These limited occurrences do not establish a strong carcinogenic link for pure anthracene.

Therefore, the International Agency for Research on Cancer (IARC) and the U.S. Environmental Protection Agency (EPA) have categorized anthracene as “not classifiable as to its carcinogenicity to humans” (IARC Category 3 and EPA Group D).

In terms of acute toxicity, oral administration of 1.7 g/kg of pure anthracene to mice had no lethal effect.

Anthracene is also absorbed through the skin. When a 14C-labeled solution in hexane or acetone (approximately 9 mg/cm3) was topically applied to rat skin, approximately 50% was absorbed within 6 days, with 29% recovered from urine, 22% from feces, and 1% from various tissues, primarily the liver and kidneys. After just 1 day, 20% of the dose was already present in the urine (around 17%) and feces (around 3%).

Anthracene is a skin sensitizer and can cause local photosensitivity. As a safety measure, a recommended threshold limit value (TLV) of 0.1 mg/m3 has been proposed to minimize potential exposure concerns.

Reference

- Anthracene; Ullmann’s Encyclopedia of Industrial Chemistry. – https://onlinelibrary.wiley.com/doi/10.1002/14356007.a02_343.pub2