2,3-Butanediol: Properties, Production and Uses

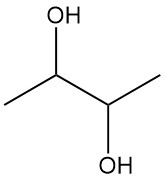

2,3-Butanediol, also known as 2,3-butylene glycol, is an organic compound with the formula C4H10O2. It is a colorless, viscous liquid that is miscible with water in all proportions. 2,3-Butanediol is a vic-diol, which means that the two hydroxyl groups are located on adjacent carbon atoms.

Table of Contents

In the past, bacterial fermentation of hexoses and pentoses yielded 2,3-butanediol. Pyrolysis of the diacetate produced high-purity butadiene, previously used for synthetic rubber production in the United States. Now, butenes derived from cracked gases serve as the primary raw material.

1. Physical Properties of 2,3-Butanediol

2,3-butylene glycol, also known as 2,3-butanediol, can exist in three different stereoisomeric forms:

- (2S,3S)-2,3-Butanediol (1): This stereoisomer is dextrorotatory, meaning it rotates plane-polarized light to the right. It has CAS number [24347-58-8].

- (2R,3R)-2,3-Butanediol (2): This stereoisomer is levorotatory, meaning it rotates plane-polarized light to the left. It has CAS number [5341-95-7].

- (R,S)-2,3-Butanediol (3): This stereoisomer is optically inactive, meaning it has no net effect on plane-polarized light. It is a meso compound and is a mixture of the (2R,3S) and (2S,3R) enantiomers.

| Property | Value |

|---|---|

| Formula | C4H10O2 |

| Molecular mass | 90.12 g/mol |

| Color | Colorless |

| Odor | Odorless |

| Hygroscopicity | Strongly hygroscopic |

| Appearance | Oily liquid or crystal |

| Taste | Sweet |

| Miscibility with water | Miscible |

| Solubility in low molecular mass alcohols and ketones | Readily soluble |

| Melting point | 23 °C (73 °F) |

| Boiling point | 177 °C (351 °F) |

| Density | 0.987 g/cm³ |

| Refractive index (at 25 °C) | 1.43 |

| Viscosity (35°C) | 65.6 mPa s |

| Flash point | 85 °C (165°F) |

| Autoignition temperature | 402 °C |

2. Chemical Reactions of 2,3-Butanediol

2,3-Butanediol is a vic-diol, which makes the molecule more reactive than other diols, such as 1,4-butanediol.

Dehydrogenation of 2,3-butanediol produces acetoin and diacetyl.

Dehydration primarily yields 2-butanone.

2,3-Butanediol is oxidized for example with periodate to form acetaldehyde; this reaction can be utilized for analytical determination.

2,3-Butanediol forms cyclic esters, acetals, and ketals with carboxylic acids and ketones or aldehydes.

When reacted with diisocyanates, it produces polyurethanes.

3. Production of 2,3-Butanediol

3.1. Production of 2,3-Butanediol from C4 Raffinate II

2,3-Butanediol is produced from C4 Raffinate II. Crack gases are processed to remove butadiene and isobutene, resulting in a C4 hydrocarbon fraction known as C4 raffinate II. This fraction contains approximately 77% butenes and 23% butane/isobutane.

C4 raffinate II undergoes chlorohydrination with a chlorine solution, followed by cyclization with sodium hydroxide. This produces a butene oxide mixture containing:

- 55% trans-2,3-butene oxide

- 30% cis-2,3-butene oxide

- 15% 1,2-butene oxide

The butene oxide mixture is hydrolyzed at 50 bar, 160-220°C with an excess of water (ΔH = -42 kJ/mol). This reaction yields a mixture of butanediols:

- meso-2,3-butanediol from trans-2-butene via trans-2,3-butene oxide

- racemic mixture of R,R- and S,S-2,3-butanediol from cis-2-butene via cis-2,3-butene oxide

The butanediol mixture is separated by vacuum fractionation, which is easier than separating the initial butene oxide mixture.

3.2. Production of 2,3-Butanediol by Fermentation

The production of 2,3-butanediol involves a mixed acid pathway, yielding various end-products such as ethanol, acetate, lactate, formate, and succinate. Acetoin, an intermediate formed during fermentation, can be metabolically converted to 2,3-butanediol. The metabolic pathways use glucose and are catalyzed by enzymes like acetoin reductase.

2,3-Butanediol exists in three stereoisomers: dextro-, levo-, and meso-forms, with their proportions depending on the microorganism used for fermentation. Various bacterial strains, such as Bacillus polymyxa, Klebsiella oxytoca, and Aeromonas hydrophila, are known producers of 2,3-butanediol.

The choice of strain and carbon source influences the stereoisomeric composition of the final product.

The production process can use different carbon sources, including glucose, xylose, glycerol, and even pentose sugars. Carbohydrates derived from natural resources like cellulosic and hemicellulosic substrates can also serve as fermentation substrates.

The fermentation process is influenced by factors like oxygen supply, pH, succinic acid concentration, and acetate levels. Oxygen availability, controlled by the oxygen transfer rate, plays a crucial role in determining the product yield and composition.

Bioreactor design and operation modes, such as continuous cell-recycle systems, can enhance productivity. Monitoring of fermentation products can be achieved by techniques like flow injection analysis and membrane-introduction mass spectrometry.

4. Uses of 2,3-Butanediol

2,3-Butanediol (predominantly meso isomer) has several important applications:

- Cross-linking agent: It serves as a cross-linking agent for naphthalene-1,5-diisocyanate in the production of specific hard-rubber products like Vulkollan.

- Insecticide derivatives: Derivatives of 2,3-butanediol play a role in the development of insecticides, such as Sapecron, an acetal formed with the N-methylcarbamate of salicylic aldehyde.

- Pharmaceutical intermediates: Various derivatives of 2,3-butanediol serve as valuable intermediates in the pharmaceutical industry.

- Humectants: 2,3-Butanediols exhibit some potential as humectants, helping retain moisture in various applications.

- Polymer and plasticizer synthesis: They find use in the synthesis of various polymers and plasticizers.

- 2,3-Butanediol can be used as a fuel additive to improve the performance of gasoline and diesel engines. It can also be used as a biofuel.

- It is a good solvent for a variety of organic compounds, including paints, inks, and adhesives.

- Flavoring agent: When converted to diacetyl, 2,3-BDL can be used as a flavoring agent in food products.

- Anti-freeze: The levo-form of 2,3-BDL has potential as an anti-freeze agent.

5. Toxicology

2,3-Butanediol has an LD50 value of 8.9 g/kg (mouse, oral)

References

- Butanediols, Butenediol, and Butynediol, Ullmann’s Encyclopedia of Industrial Chemistry. – https://onlinelibrary.wiley.com/doi/10.1002/14356007.a04_455.pub2

- Biological production of 2,3-butanediol – https://link.springer.com/article/10.1007/s002530000486