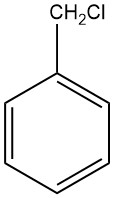

Benzyl chloride, also known as α-chlorotoluene, is a toluene derivative with chlorine substitution in the side chain. It is a colorless liquid withthe chemical formula C7H7Cl.

Benzyl chloride is an important compound with many industrial applications that was originally synthesized by S. Cannizzaro in 1853 by the reaction between benzyl alcohol and hydrochloric acid.

Table of Contents

1. Physical Properties of Benzyl Chloride

Benzyl chloride is a colorless liquid with a strong, pungent odor. It is a potent lachrymator, causing intense irritation to both the eyes and mucous membranes.

Here are some key physical properties of benzyl chloride:

| Property | Value |

|---|---|

| Molecular Weight | 126.58 g/mol |

| Boiling Point at 101.3 kPa | 179.4 °C |

| Melting Point | -39.2 °C |

| Density (ρ) at 10°C | 1.1188 g/cm³ |

| Density (ρ) at 20°C | 1.1081 g/cm³ |

| Density (ρ) at 30°C | 1.1004 g/cm³ |

| Density (ρ) at 50°C | 1.0870 g/cm³ |

| Density (ρ) at 87°C | 1.072 g/cm³ |

| Refractive Index | 1.5389 |

| Dynamic Viscosity (η) at 15°C | 1.501 mPa s |

| Dynamic Viscosity (η) at 20°C | 1.38 mPa s |

| Dynamic Viscosity (η) at 25°C | 1.289 mPa s |

| Dynamic Viscosity (η) at 30 °C | 1.175 mPa s |

| Surface Tension (σ) at 15 °C | 38.43 mN/m |

| Surface Tension (σ) at 20 °C | 37.80 mN/m |

| Surface Tension (σ) at 30 °C | 36.63 mN/m |

| Surface Tension (σ) at 88°C | 29.15 mN/m |

| Surface Tension (σ) at 17 °C | 19.5 mN/m |

| Specific Heat at 0°C | 178 J mol⁻¹ K⁻¹ (1403 J kg⁻¹ K⁻¹) |

| Specific Heat at 20 °C | 181 J mol⁻¹ K⁻¹ (1432 J kg⁻¹ K⁻¹) |

| Specific Heat at 25 °C | 183 J mol⁻¹ K⁻¹ (1444 J kg⁻¹ K⁻¹) |

| Specific Heat at 50 °C | 189 J mol⁻¹ K⁻¹ (1495 J kg⁻¹ K⁻¹) |

| Specific Heat at 100 °C | 212 J mol⁻¹ K⁻¹ (1675 J kg⁻¹ K⁻¹) |

| Heat of Vaporization at 25 °C | 50.1 kJ/mol (396 kJ/kg) |

| Heat of Combustion at Constant Volume | 3708 kJ/mol (29.29 × 10³ kJ/kg) |

| Flash Point | 60°C |

| Ignition Temperature | 585°C |

| Explosive Limits in Air | Lower: 1.1 vol% Upper: 14 vol% |

| Explosive Limits in Chlorine | Lower: Approximately 6 vol% Upper: Approximately 60 vol% |

| Specific Conductivity at 20 °C | 1.5 × 10⁻⁸ S/cm |

| Vapor Pressure at 0°C | 0.025 kPa |

| Vapor Pressure at 10 °C | 0.05 kPa |

| Vapor Pressure at 20 °C | 0.12 kPa |

| Vapor Pressure at 30 °C | 0.37 kPa |

| Vapor Pressure at 50 °C | 0.99 kPa |

| Vapor Pressure at 100 °C | 7.96 kPa |

| Vapor Pressure at 130 °C | 23.40 kPa |

| Vapor Pressure at 179.4 °C | 101.33 kPa |

Benzyl chloride forms various azeotropes, and examples can be found in the following table:

| Component | boiling point, °C | Benzyl chloride, wt % |

|---|---|---|

| Benzaldehyde | 178 | 50 |

| Hexanoic acid | 179 | 95 |

| Isovaleric acid | 171 | 38 |

| Valeric acid | 175 | 25 |

| Ethyl acetoacetate | 175 | 35 |

| Methyl acetoacetate | 167 | <80 |

| 1,3-Dichloro-2-propanol | 169 | 57 |

| 2,3-Dichloro-2-propanol | 171 | 40 |

| Ethylene glycol | ca. 167 | ca. 30 |

Benzyl chloride solubility in water varies with temperature, being 0.33 g/L at 4 °C, 0.49 g/L at 20 °C, and 0.55 g/L at 30 °C. It readily dissolves in solvents such as chloroform, acetone, acetic esters, diethyl ether, and ethanol.

The solubility of chlorine in 100 g of benzyl chloride changes with temperature, reaching 8.0 g at 30 °C, 5.4 g at 50 °C, and 2.1 g at 100 °C.

2. Chemical Reactions of Benzyl Chloride

Benzyl chloride is a starting material for the synthesis of benzal chloride and benzotrichloride by side-chain chlorination. Nuclear chlorination produces chlorobenzyl chlorides. It is oxidized in an aqueous solution with sodium dichromate and sodium carbonate to form benzaldehyde and benzoic acid.

Benzyl chloride reacts with metals to produce different products. For example, it reacts with magnesium in diethyl ether to form benzyl magnesium chloride, a Grignard reagent. With copper powder or sodium, it produces 1,2-diphenylethane as the main product in the Wurtz synthesis.

It reacts with strong Lewis acid catalysts such as FeCl3, AlCl3, and ZnCl2 to form Friedel–Crafts self-condensation products of the (C7H6)n type. However, these polymers are not commercially significant despite the ability to control the degree of condensation by changing the reaction conditions.

It reacts with benzene or toluene in the presence of Friedel–Crafts catalysts to form diphenylmethane or the isomeric benzyltoluenes, respectively.

Benzyl chloride reacts with hydrogen sulfide and alkali metals to produce benzyl mercaptan and dibenzyl sulfide, respectively. Its reaction with sodium salts of carboxylic acids produces the corresponding benzyl esters.

It forms benzyl alcohol when hydrolyzed with hot water, but this reaction is not industrially used because the benzyl alcohol formed is re-formed into benzyl chloride by the hydrochloric acid formed in the process. It also promotes the formation of dibenzyl ether. However, hydrolysis in the presence of alkali does yield benzyl alcohol.

Benzyl chloride reacts with sodium cyanide to produce phenylacetonitrile (benzyl cyanide). When reacted with ammonia or amines, it yields primary, secondary, tertiary amines, and quaternary ammonium salts.

The reaction with hexamethylenetetramine produces benzaldehyde, known as the Sommelet reaction.

3. Production of Benzyl Chloride

3.1. Reaction Mechanism

The process of chlorination of toluene involves two distinct mechanisms: radical chain and electrophilic polar mechanisms. The radical chain mechanism consists of several steps:

1. Chain Initiation:

- Chlorine gas is initiated by light energy (hν), producing two chlorine radicals (2 Cl•).

2. Chain Propagation:

- Chlorine radicals (Cl•) react with the aliphatic side chain (RH), forming a methyl radical (R•) and hydrogen chloride (HCl).

- Methyl radicals (R•) then react with more chlorine (Cl2), producing methyl chloride (RCl) and more chlorine radicals (Cl•).

3. Chain Termination:

- Chlorine radicals (Cl•) can terminate the chain by combining to form chlorine gas (Cl2).

- Methyl radicals (R•) can also terminate the chain by reacting with each other to form dimethyl compounds (RR).

This chlorination process is highly exothermic, releasing energy in the range of 96 to 105 kJ/mol of chlorine. Due to the rapid formation of chlorine radicals and the displacement of hydrogen, radical chain lengths can vary from 103 to 106, depending on the substrate and reaction conditions.

Because side-chain chlorination and nuclear chlorination follow fundamentally different mechanisms, it is possible to achieve selectivity. To ensure high efficiency in side-chain chlorination, certain conditions must be met:

- Optimal Radical Concentration: Maintain an ideal concentration of radicals.

- Eliminate Electrophilic Effects: Remove components that could introduce electrophilic reactions.

- Prevent Chain Termination: Eliminate substances that can prematurely terminate radical chains.

- Avoid Side Reactions: Minimize conditions that lead to unwanted reactions.

- Promote Radical Reactions: Take precautions that favor radical reactions over electrophilic ones.

Addressing each of these points:

1. Chlorine radical formation can be enhanced using radical-forming agents like 2,2´-azobis(isobutyronitrile) (AIBN), benzoyl peroxide, or elevated temperatures (100–200 °C). Irradiation with UV light or β radiation can also excite chlorine molecules.

2. Friedel–Crafts catalysts favor nuclear chlorination. Therefore, the starting materials should be free of substances that promote nuclear chlorination, such as iron salts. Reactor materials like glass, glass-lined steel, and polytetrafluoroethylene are preferred.

3. Oxygen is a radical scavenger, and its presence should be minimized. Distilled chlorine or purging with an inert gas can help remove oxygen.

4. Water can lead to the formation of hydrochloric acid and may cause hydrolysis of the chlorinated compounds. Hydrogen chloride formed during chlorination can contribute to nuclear chlorination.

5. Excessive chlorine concentrations can lead to unwanted side reactions. Introducing an inert gas into the chlorine stream and using smaller reactor units can help mitigate this issue.

During the radical chlorination of toluene, all three hydrogen atoms in the side chain are progressively replaced by chlorine, resulting in mixtures of benzyl chloride, benzal chloride, and benzotrichloride.

3.2. Production Process

To produce benzyl chloride with minimal production of secondary products like benzal chloride and benzotrichloride, one approach is to limit chlorination to only 30-40% of the toluene input and then separate the resulting mixture through fractionation.

Another method is to use alkyl or aryl sulfides as radical chain initiators to monochlorinate the side-chain without the need for UV light.

In modern industrial processes, benzyl chloride is produced via side-chain chlorination of toluene in continuous loop-type photoreactors made from glass-lined steel or glass. Older methods using silver, lead, or nickel-lined reaction columns have been discontinued due to corrosion issues.

In the continuous process, chlorination is typically limited to 20-40% of the toluene input to minimize the formation of higher chlorinated byproducts. The resulting mixture, still containing significant toluene and typically 0.5-2% benzal chloride, undergoes distillation.

During distillation, high boilers are separated for further purification, and toluene is recycled back to the reactor.

Online near-infrared spectroscopy is used to monitor the composition of the reaction mixture in chlorination reactors and distillation units, allowing efficient control of toluene and chlorine feeds in the continuous process. However, the main drawback of this method is the high cost associated with distillation processes due to the substantial quantity of recycled toluene.

A typical plant setup for continuous benzyl chloride production is shown in Figure 1.

Fresh toluene enters the pre-chlorinator (R0) and then flows through a cascade of four additional photoreactors (R1-R4), supplied with chlorine in precisely measured amounts, with decreasing chlorine levels from reactor to reactor.

Typically, the last reactor in the cascade is purged with pure nitrogen to remove dissolved chlorine gas from the reaction mixture before purification. In the subsequent raw distillation (C1), unreacted toluene is removed, leaving benzyl chloride (along with small amounts of benzal chloride) in the distillation sump.

The chlorinated raw product is directed to the fine distillation unit (C2) for further purification to achieve the final quality. The remaining sump product is a mixture of benzyl and benzal chlorides, suitable for recycling in the production of benzal chloride or benzotrichloride.

The combined off-gases from the reactors are returned to the pre-chlorinator (R0), where residual chlorine reacts with fresh or recycled toluene.

The chlorine-free off-gas, primarily composed of hydrogen chloride and nitrogen, undergoes treatment in a scrubber system where HCl is absorbed by water, yielding concentrated hydrochloric acid of technical quality.

Alternatively, pure benzyl chloride can be produced through vapor-phase chlorination in specialized reactors, maintaining the temperature at the chlorine feed point within the range of the boiling points of toluene and benzyl chloride.

Under these conditions, benzyl chloride is rapidly condensed and collected, while hydrogen chloride leaves at the top, and toluene is liquefied and recycled. The reactor operates continuously, and the bottom product typically consists of 0.9% toluene, 93.6% benzyl chloride, and 5.5% distillation residue.

This method carries inherent risks, including the ignition temperature of toluene in chlorine gas (185 °C) and the explosive nature of toluene-chlorine and benzyl chloride-chlorine mixtures over a wide range of concentrations.

Another approach to producing benzyl chloride involves the chloromethylation of benzene, although this method lacks commercial significance.

4. Uses of Benzyl Chloride

Benzyl chloride is used to produce benzyl alcohol, benzyl butyl phthalate, phenylacetic acid, and quaternary ammonium salts. It is also used to produce benzyl esters, triphenylmethane dyes, dibenzyl disulfide, benzylphenol, and benzylamine.

Benzyl alcohol is used as a solvent, fragrance, and antiseptic. Benzyl butyl phthalate is a plasticizer used in polyvinyl chloride (PVC). Phenylacetic acid is used to produce synthetic penicillin. Quaternary ammonium salts are used as disinfectants and phase-transfer catalysts.

Benzyl esters are used in the flavors and fragrances industry. Triphenylmethane dyes are used as dyes and pigments. Dibenzyl disulfide is an antioxidant used in lubricants. Benzylphenol is used as a stabilizer for polymers. Benzylamines are used as pharmaceuticals and intermediates in the production of other chemicals.

5. Toxicology of Benzyl Chloride

The acute oral toxicity of benzyl chloride in rats is 1230 mg/kg, and in mice, it is 1620 mg/kg. However, the REACH registration dossier suggests a lower LD50 value of 560 mg/kg in rats. When administered subcutaneously in an oil solution, the LD50 in rats is 1000 mg/kg.

Exposure to benzyl chloride at concentrations of 100-1000 mg/m3 for 2 hours in rats and mice resulted in irritation of the mucous membranes and conjunctivitis.

In a subchronic repeated-dose study involving rats, severe acute and chronic gastritis in the forestomach, often accompanied by ulcers, as well as acute myocardial necrosis and edema of the heart, were the primary causes of death.

Benzyl chloride is known to be a potent skin-sensitizing agent for guinea pigs and exhibits weak mutagenic properties.

In experiments with rats, subcutaneous injections of weekly doses of 80 mg/kg over one year, followed by a post-observation period, led to the development of local sarcomas with lung metastases. The mean induction time for these tumors was 500 days.

Dermal application of benzyl chloride in mice resulted in the observation of skin carcinomas.

A subsequent study on the carcinogenicity of benzyl chloride administered in corn oil found statistically significant increases in thyroid C-cell tumors in female rats and various types of tumors, including hemangiosarcoma, forestomach carcinoma, and lung alveolar-bronchiolar carcinoma in mice, in a dose-dependent manner.

Benzyl chloride is readily absorbed from the lungs and gastrointestinal tract. After oral administration, it leads to the excretion of various compounds in urine, including N-acetyl-S-benzylcysteine, benzyl alcohol, benzaldehyde, and benzoic acid.

For humans, exposure to a concentration of 16 ppm of benzyl chloride in the air is considered intolerable within just one minute. It is a potent lachrymator, causing strong irritation to the eyes, nose, and throat, and has the potential to induce lung edema.

Although there is limited evidence regarding the carcinogenicity of α-chlorinated toluenes and benzoyl chloride in humans, based on available data and sufficient evidence of carcinogenic effects in animals, benzyl chloride is classified as probably carcinogenic to humans according to various classification systems, including GHS (category 1B), IARC (category 2A), and MAK classification (category 2).

Reference

- Benzyl Chloride and Other Side-Chain-Chlorinated Aromatic Hydrocarbons; Ullmann’s Encyclopedia of Industrial Chemistry. – https://onlinelibrary.wiley.com/doi/abs/10.1002/14356007.o04_o01.pub2