2-Methyl-2-propanol: Properties, Production and Uses

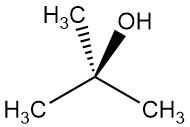

2-Methyl-2-propanol, also known as tert-butanol, is the simplest tertiary alcohol with the chemical formulat (CH3)3COH. It is a colorless, solid crystal at room temperature. However, it melts near room temperature (26 °C) to become a viscous liquid with a camphor-like odor.

Table of Contents

1. Physical Properties of 2-Methyl-2-propanol

2-Methyl-2-propanol is a colorless solid at room temperature. It is completely miscible with water, ethanol, and diethyl ether and common organic solvents.

The major characteristic physical properties of 2-methyl-2-propanol are presented in Table 1.

| Property | Value |

|---|---|

| Molar mass | 74.12 g/mol |

| Melting point | 25.6 °C |

| Boiling point | 82.55 °C |

| Density at 20 °C | 0.7867 g/cm³ |

| Refractive index at 20 °C | 1.3841 |

| Viscosity at 20 °C | 5.5 mPa⋅s |

| Specific heat | 3.035 J g⁻¹ K⁻¹ |

| Heat of vaporization | 535.78 J/g |

| Heat of fusion | 91.61 J/g |

| Heat of combustion | 35.694 kJ/g |

| Critical pressure | 39.7 hPa |

| Critical temperature | 235 °C |

| Surface tension at room temp. | 20.0 (25°C) mN/m |

| Dielectric constant at room temp. | 11.4 |

| Solubility in water | miscible |

| Flash point | 11 °C |

| Ignition limits in air, vol% | 2.3 - 8 % |

| Ignition temperature | 470 °C |

2. Chemical Reactions of 2-Methyl-2-propanol

2-Methyl-2-propanol easily undergoes dehydration to form 2-methylpropene (isobutene) with dilute sulfuric acid and heating. This reaction is not industrially important due to the availability of 2-methylpropene from cracked petroleum.

It cannot be selectively dehydrogenated due to molecule splitting under extreme conditions.

Tert-butanol can be used in diverse alkylation reactions with ammonia, amines, and aromatic compounds.

It is converted to tert-butyl esters with inorganic and organic acids using acid catalysts, but it is less reactive than primary and secondary alcohols.

2-Methyl-2-propanol is deprotonated with sodium or potassium metal to produce the corresponding alkoxide. Potassium tert-butoxide is a common example of non-nucleophilic base in organic chemistry.

It removes acidic protons from basic substrates, but its bulky structure prevents its participation in nucleophilic substitution reactions like Williamson ether synthesis or SN2 reactions.

Tert-butanol reacts with hydrogen chloride and hypochlorous acid to produce tert-butyl chloride and tert-butyl hypochlorite, respectively.

3. Production of 2-Methyl-2-propanol

2-Methyl-2-propanol is produced industrially by two main processes:

- 2-Methylpropene hydration

- As a byproduct of propylene oxide and methyl tert-butyl ether production

3.1. Production of 2-Methyl-2-propanol by 2-Methylpropene Hydration

2-Methyl-2-propanol is primarily produced by the hydration of 2-methylpropene (isobutene). This process involves the following steps:

Reactant Preparation: Isobutene, the primary feedstock, is often derived from catalytic cracking of petroleum or dehydrogenation of n-butane. Water, acting as the hydration agent, is typically supplied as purified water or recycled from previous stages. Tert-butanol itself may be present in the feedstock or intentionally added to the reaction.

Catalysis: Sulfonic acid-functionalized cation exchange resins serve as the favored catalysts due to their high activity, selectivity towards 2-methyl-2-propanol formation, and ease of regeneration. Reaction conditions, including temperature (typically between 30-120 °C) and pressure (atmospheric or slightly elevated), are meticulously controlled to optimize conversion and minimize undesirable side reactions.

Reaction and Product Formation: The hydration reaction, a reversible process, converts isobutene and water into tert-butanol. Multi-stage reactors are often employed to efficiently utilize the catalyst and maximize conversion. Precise control of reactant ratios, temperature, and catalyst loading is crucial for ensuring high selectivity.

Product Separation: Distillation effectively separates the desired tert-butanol product from unreacted isobutene, inert hydrocarbons, and water. Unreacted isobutene and water can be recycled back into the process to enhance resource efficiency.

3.2. Byproduct of propylene oxide and methyl tert-butyl ether production

2-Methyl-2-propanol is formed as a valuable byproduct in several industrial processes, particularly those involving propylene oxide and methyl tert-butyl ether.

1. Propylene Oxide Production:

During the manufacture of propylene oxide from 2-methylpropane (isobutane), roughly 1.2 tons of tert-butanol are generated per ton of propylene oxide produced. The process involves an intermediate step where t-butyl hydroperoxide forms from isobutane.

2. Methyl tert-butyl Ether Processing:

Splitting methyl tert-butyl ether into pure 2-methylpropene or 2-methyl-2-propanol can yield tert-butanol as a byproduct. Similarly, methyl tert-butyl ether synthesis with trace water in the feedstock (methanol and C4-olefins) also generates tert-butanol as an undesired byproduct.

The presence of tert-butanol as a byproduct requires additional steps for separation and purification, increasing production costs. However as avantages, it provides a readily available source of 2-methyl-2-propanol for downstream applications, minimizing reliance on dedicated production methods and enhancing process efficiency.

Although not commercially used, tert-butanol can also be produced via Grignard reaction by reacting acetone with methylmagnesium chloride.

4. Uses of 2-Methyl-2-propanol

Compared to other butanols, 2-methyl-2-propanol (t-BuOH) holds a minor share in global consumption. However, its use has steadily grown since 1990 before reaching a plateau in recent years.

- 2-Methyl-2-propanol finds its primary use as a solvent due to its favorable properties, including miscibility with water and organic compounds.

- Tert-butanol is used as a reagent for introducing the tert-butyl group into organic molecules. This modification is employed in various applications, such as the synthesis of oil-soluble resins (e.g., tert-butylphenol) and antioxidants (e.g., trinitro-tert-butyltoluene).

- It is also an important starting material for the production of organic peroxides, which serve as essential polymerization catalysts in various industrial processes.

- 2-Methyl-2-propanol competes with 2-propanol as an additive in gasoline to prevent carburetor icing. Its methyl ether briefly emerged as an octane booster and lead replacement in the 1980s and 90s, experiencing a significant surge in consumption (0.17 to 19 million tons between 1982 and 1997). However, environmental concerns led to its eventual replacement by direct blending of bioethanol with gasoline.

5. Toxicology of 2-Methyl-2-propanol

2-Methyl-2-propanol exhibits relatively low acute toxicity. The lowest documented LD50 values are 2,740 mg/kg (oral, rats) and 2,000 mg/kg (dermal, rabbits).

Effects of Exposure:

- Acute: At high exposure levels, tert-butanol has a narcotic effect, characterized by headache, nausea, fatigue, and dizziness.

- Skin: Prolonged contact with 2-methyl-2-propanol in rabbits did not cause skin irritation. In humans, slight erythema and hyperemia may occur following skin contact.

- It has a distinct, unpleasant odor.

Exposure Limits:

- Threshold Limit Value (TLV): 100 ppm (Time-Weighted Average), 150 ppm (Short-Term Exposure Limit).

- MAK Value (Maximum Workplace Concentration): 20 mL/m³.

- TRGS 900 (German Technical Regelwerk for Hazardous Substances): 20 mL/m³.

References

- Butanols; Ullmann’s Encyclopedia of Industrial Chemistry. – https://onlinelibrary.wiley.com/doi/10.1002/14356007.a04_463.pub3

- Process for production of tertiary butyl alcohol. – https://patents.google.com/patent/US4307257A/en

- Process for the preparation of tert-butanol. – https://patents.google.com/patent/EP1431264A1/en

- https://en.wikipedia.org/wiki/Tert-Butyl_alcohol